Products

OVMS/D Thin pad and pillow wholesale mattress coiling spring machine

| Product Name | Pocket spring machine | ||

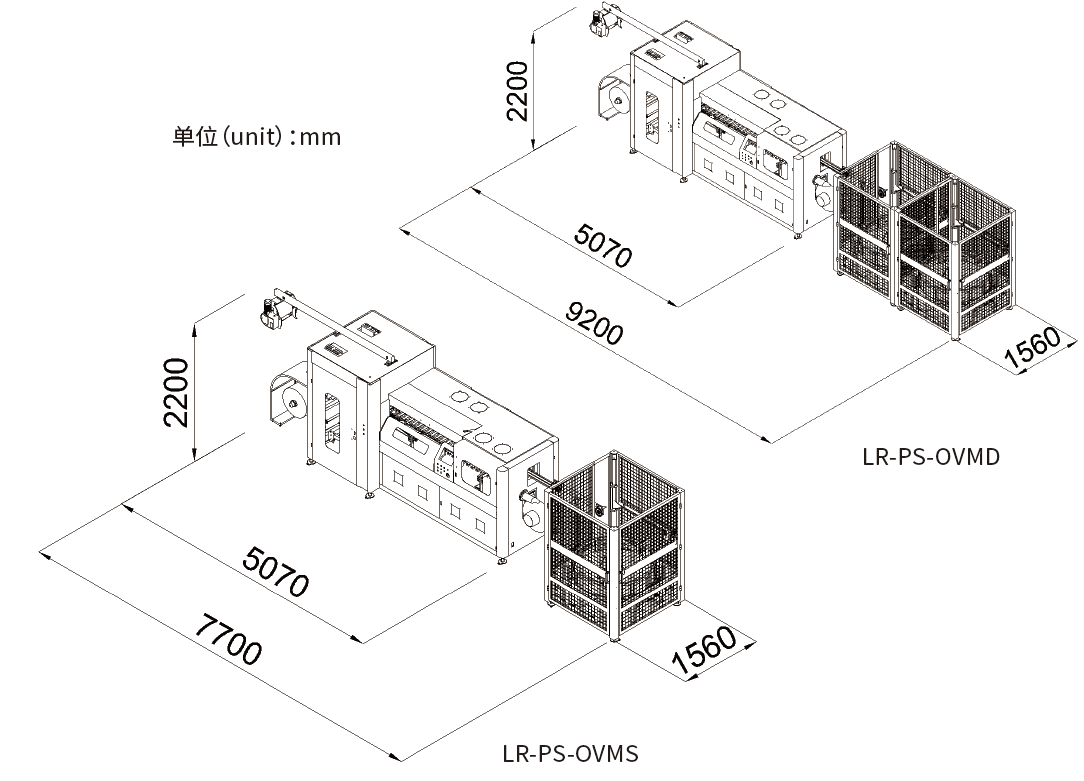

| Model | LR-PS-OVMS | LR-PS-OVMD | |

| Production capacity | 120 springs/min | ||

| Coiling head | Single wire servo coiling head/ Double wire servo coiling head |

||

| Working principle | Servo control | ||

| Spring shape | Standard versions: barrel and cylindrical |

||

| Air consumption | Approx. 0.2m³/min. | ||

| Air pressure | 0.6-0.7Mpa | ||

| Power consumption in total | Approx.40KW | Approx. 43KW | |

| Power requirements | Voltage | 3AC 380V | |

| Frequency | 50/60Hz | ||

| Input current | 60A | 65A | |

| Cable section | 3*16 m㎡ + 2*10 m㎡ | ||

| Working temperature | +5℃ - +35℃ | ||

| Weight | Approx.4000Kg | Approx.5000Kg | |

| Consumption Material Deta | |||

| Non-woven fabric | |||

| Fabric density | 65-90g/m2 | ||

| Fabric width | 170-420mm | ||

| Inner dia.of fabric roll | 75mm | ||

| Outer dia.of fabric roll | Max.1000mm | ||

| Steel wire | |||

| Wire diameter | 1.0-1.4mm | ||

| Inner dia.of wire roll | Min.320mm | ||

| Outer dia.of wire roll | Max.1000mm | ||

| Acceptable weight of wire roll | Max.600Kg | ||

| Wire Diameter | Spring Waist Diameter | Pocket Spring Height | |

| Option 1 | φ1.0-1.2mm | φ30-42mm | 40-130mm |

| Option 2 | φ1.3-1.4mm | φ36-45mm | 40-140mm |

Heat-treatment and spring rebound

Are you in the market for a high-quality wholesale mattress coiling spring machine that specializes in producing thin pad and pillow products? Then look no further because the OVMS/D Thin Pad and Pillow Coiling Spring Machine is the perfect machine for your needs!

This specialized coiling spring machine is designed to produce thin pad and pillow products in bulk quantities at a wholesale price. It is equipped with the latest technology and advanced features, making it efficient and easy to use. With its high-speed capabilities, this coiling spring machine is capable of producing up to 80 mattresses per hour, which is perfect for meeting the demands of high-volume production.

Why choose us?

1.Ultra miniature, specialized equipment for thin cushions and pillows.

This is a pocket spring production machine for making pillow stuffing, we can use this produced pocket spring for pillow elastic stuffing, and also for sofa, cushion, car seat and many other scenarios.

2.Good support and low cost.

The equipment can be used to produce pillow fillings with the advantages of good air permeability, good support and low cost.It can strengthen the support at the cervical position, making the pillow more ergonomic.

3. Replace sponge function

The pocket springs produced by the equipment can be used on sofa upholstery with the advantages of comfort, breathability, environmental protection, etc., with certain sponge replacement function.

Why choose us?

1. Brand advantage: Lianrou machinery brand has been in continuous operation for more than 20 years, focusing on the field of upholstered furniture machinery and equipment. Its products sell well in 150 countries around the world, and are favored by many international big brands.

2. Technical advantages: Professional technical research and development team, more than 200 patented technologies, developed a variety of industry-first equipment and a variety of green and environmentally friendly mattress solutions. The product has a high degree of intelligence, high production efficiency, and a small footprint.

3. Quality advantage: The product has a one-year worry-free warranty and strict quality management. It has passed the ISO9001 quality management system certification, and the product meets CE certification.

4. After-sales service: Global after-sales service network, on-site installation, commissioning and maintenance, and remote after-sales operation and maintenance. The powerful SMARTLINE Internet of Things system assists after-sales service.

4. After-sales service: Global after-sales service network, on-site installation, commissioning and maintenance, and remote after-sales operation and maintenance. The powerful SMARTLINE Internet of Things system assists after-sales service.