For many years, Lianrou Machinery has been committed to the research, development and production of high-level, high-technology, high-performance upholstery equipment to effectively solve many problems in the production of downstream industries. We provide downstream enterprises with comprehensive support for industrial upgrading, intelligent production and digital transformation in terms of hardware, software and intelligent production solutions.

The related upholstery equipment sells well in more than 80 countries and regions such as Europe, North America, South America, Southeast Asia, etc. The main customers include IKEA, Sealy, Yalan, Simmons, Serta, and other international famous home furnishing enterprises.

The company has a number of provincial R & D platform qualification, a professional R & D design team, including upholstered furniture hardware equipment design and development and related software development, is committed to solving a variety of problems in the upholstered furniture manufacturing industry. There have been a number of design achievements that have been recognised by the industry, including non-glue pocket spring unit production solutions, low-cost pocket spring unit production solutions, various mattress packing solutions. We can also design customised solutions according to customer requirements.

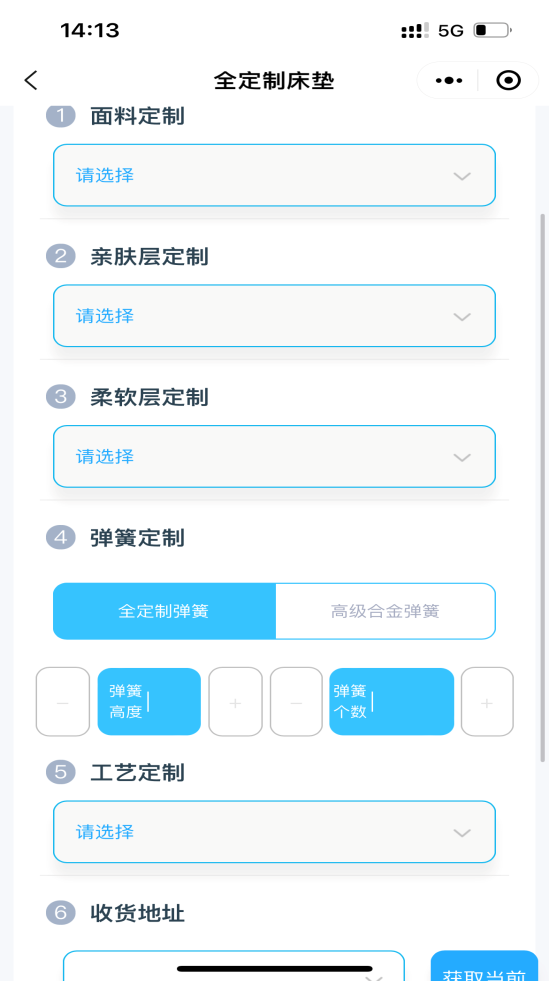

1. Customised mattress production solutions

Personalisation: simple customisation of mattress size, materials, colours and patterns.

Personalised sleep pressure curve mattress customisation: According to the sleep pressure data, analyse the required support data of the corresponding position and adjust the spring parameters of the corresponding position to achieve a perfect personalised fit.

Partition customisation: according to the user's height, weight, husband and wife's usual sleeping position, etc. Soft and hard mattress partitions can be adjusted to achieve different positions with different levels of support, protecting the spine and ensuring healthy and comfortable sleep.

Lianrou Machinery develops the Deep Sleep System, which meets the data collection and online ordering of mattress customisation, including size customisation, fabric customisation, comfort layer customisation, process customisation, spring customisation, and so on. LR-PSLINE-DL, the industry's first fully automatic double-layer pocket spring production line, meets the ergonomics of personalised curved mattress customisation and produces double-layer pocket spring mattress cores with gradual change of support according to the pressure data of the human body's sleeping position. A variety of models of pocket spring production machine can meet the zoning customised mattress production, can be a simple 5-zone, 7-zone zoning, but also double bed left and right zoning, but also in the mattress around the reinforcement of zoning and so on.

2. Special purpose mattress production solutions

Mattresses used for electric beds.

Mattresses for special populations requiring long-term care.

The mattress is movable, adjustable inclination, bending angle, better breathability, etc.

The LR-PS-CL pocket spring mattress production machine developed by Lianrou Machinery Co., Ltd. produces pocket spring mattresses with curved and inclined pocket encapsulation, which achieves a greater curvature of the pocket spring mattress. In the production, the comfort layer and pocket springs are formed once, at the same time in the pocket springs at both ends of the welding (ultrasonic welding) of the comfort layer materials, the formation of the mattress core, without the need to bond the sponge and other comfort layer materials into a complete mattress.

3.Low weight, low cost mattress production solutions.

By increasing the compression ratio of the spring. The High Compression Ratio Pocket Spring Machine, LR-PS-UMS/UMD, uses Ultra High Compression Ratio Encapsulation Technology to increase the firmness of pocket spring mattresses by compressing and encapsulating a greater percentage of the finer wire diameters. This solution reduces the weight of the mattress without compromising the support characteristics of the mattress.

By changing the arrangement of the springs. LR-PS-CL, the pocket springs assume a tilted position in the pocket encapsulation, saving 1/3 of the springs in a mattress.

4. Eco-friendly mattress production solutions

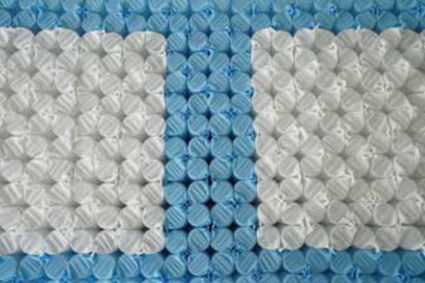

non-glue pocket spring mattress core

LR-PSA-GLL, which can be used to produce non-glue four-leaf clover structure mattress cores, has changed the traditional way of forming pocket spring mattress cores with gluing technology, and by using one-piece ultrasonic welding technology, it makes the mattress core structure more stable and environmentally friendly, and effectively reduces the cost of materials used in the production of pocket spring mattress cores, and reduces the release of formaldehyde, benzene and other hazardous substances in the glue.

Box spring production line LR-PSLINE-BOX230/BOX4W for the production of one-piece, ultra-thin, non-glue pocket spring mattress cores with ultra-high production efficiency and the production of box springs for a wide range of applications, replacing foam in a number of application scenarios.

Easily removable pocket spring mattress core, allows easy disassembly at home, just pull gently and the spring and fabric separate easily.

5.Solutions for the production of high-end pocket spring mattresses

High density, large height-to-waist ratio.LR-PS-HMS/HMD, adopts the way of reducing the waist diameter of the spring and increasing the density of the spring to increase the overall comfort of the mattress, and a mattress uses 3K-4K pocket springs for a more direct elasticity feedback.

6. Packaging solution for mattresses

Mattress flat packaging solution, LR-MP-55P-LINE, high efficiency mattress flat packaging machine, uses PE film or kraft paper for flat packaging. This packaging line uses virtual synchronization and digital twin technology to reduce labour costs. By integrating several mattress wrapping processes into one, the mattress wrapping efficiency is 35 seconds per sheet, greatly improving the overall efficiency of mattress wrapping. The line can also be used separately to wrap PE film or Kraft paper separately.

Compression roll package solution, for multiple mattresses, mattress core packaging, by compressing the compression of the roll package, compressed volume, easy to transport.LR-KPLINE-26P, there are a variety of packaging methods, direct roll compression packaging, flat compression folded roll package, pre-flat compression function, etc., suitable for borderless pocket spring mattresses, sponge mattresses, latex mattresses, Bonnell spring mattress cores, and so on.

Compression folding roll-packing is a practical solution for compressing and folding mattresses sold online. The fully automatic mattress roll packing machine, LR-KPLINE-27P, can pack mattresses into boxes with a 60cm side length, making them easily transportable in car trunks. This is convenient for both online sales and logistics transportation, as well as making it easier to move mattresses in elevators.

Additional options for packaging mattresses include automatic packing, encapsulation, large-volume sponge packaging, pillow compression packaging, and more.

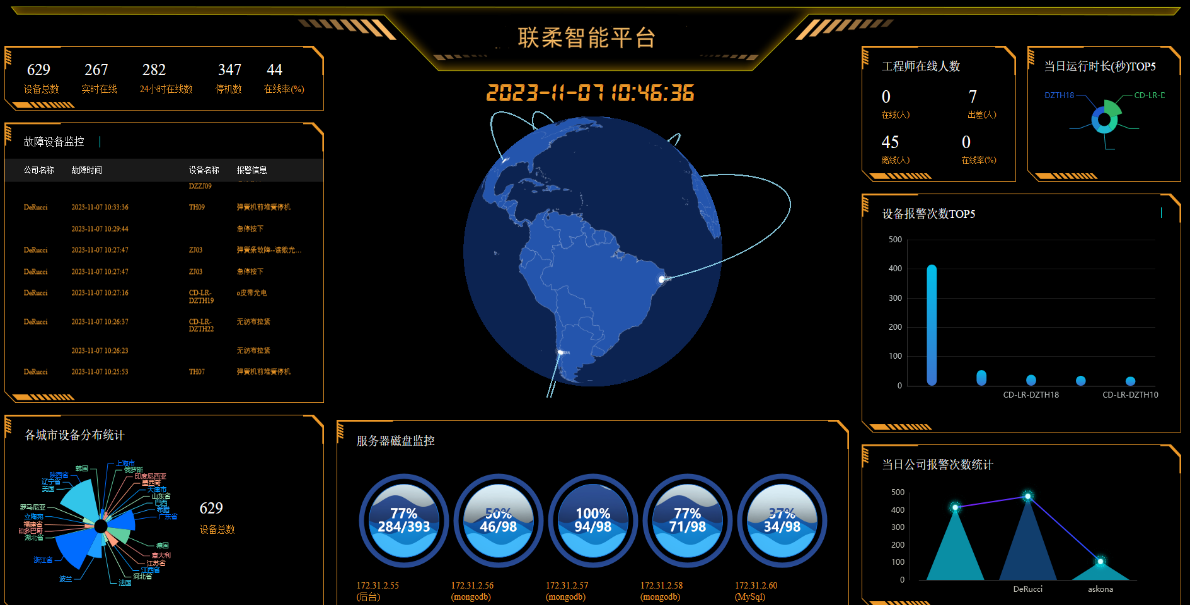

7. Smart Production Solutions.

SMART LINE Lianrou Intelligent Platform is an IoT system that effectively manages operations. It streamlines equipment monitoring, fault analysis, cost management, quality tracking, order scheduling, performance evaluation, and precise statistical report generation. The platform also has features for remote operation, maintenance, debugging, and related functions that facilitate the digitalization and smart management of mattress production. Additionally, it helps other businesses to implement digital transformation in their production facilities.

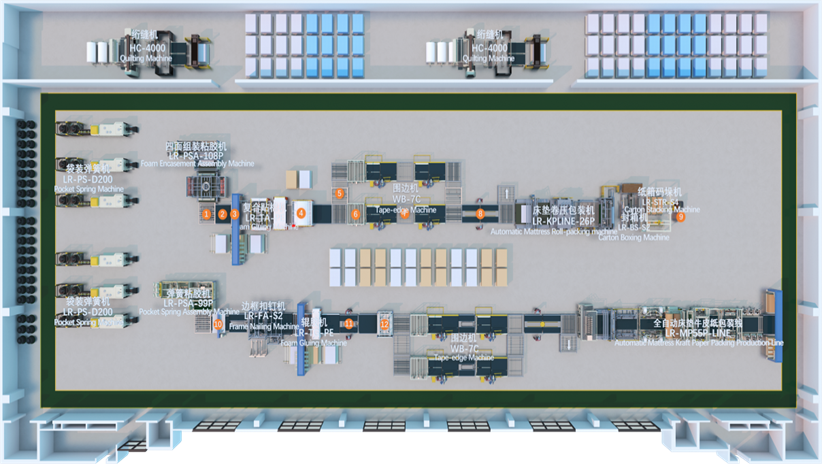

8. Intelligent production workshop case

The whole process of mattress production automation design, hardware and software solutions. Includes pocket spring mattress core production, quilting, edge, comfort layer bonding, finished mattress packaging and other mattress production process, greatly reducing labor costs.

Post time: Nov-17-2023