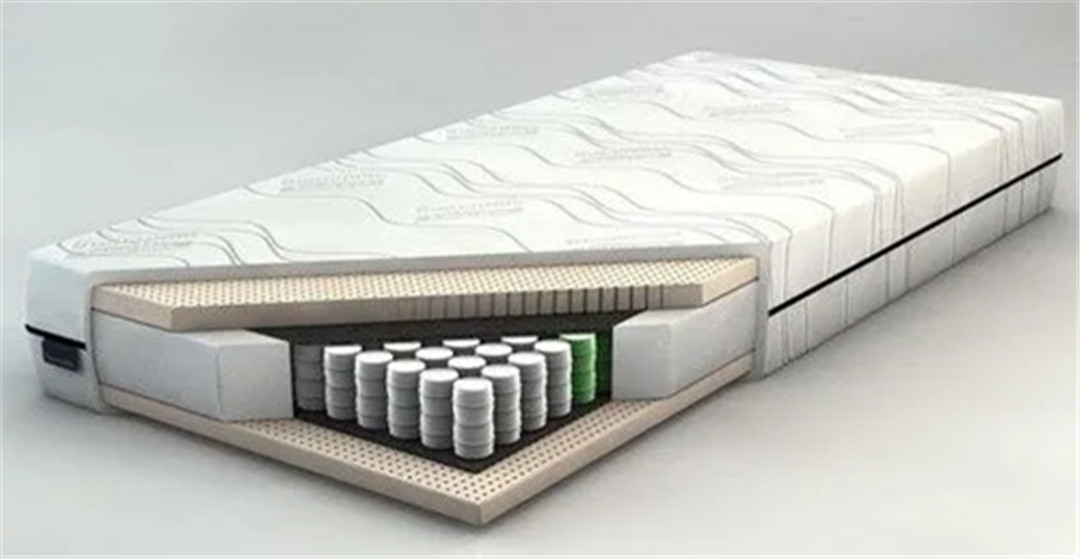

Pocketed spring mattress "core"

In an individual pocket spring mattress, each pocket spring is independently operated, independently supported and independently retracted, so that even if one of the two people lying on the mattress turns over or leaves, the other will not be affected in the slightest, thus ensuring a peaceful and comfortable sleep, and the mattress core is both healthy and environmentally friendly.

Each spring is individually sealed in a tough non-woven bag, which effectively prevents some common problems such as mould or insect infestation, as well as noise caused by the springs rubbing or squeezing together.

Common pocket spring mattress core

The mattress consists of a single layer and a single size of individual pocket springs, the softness of the mattress is influenced by the steel wire specification and the compression height of the pocket. This is the entry-level choice for the pocket spring mattress industry.

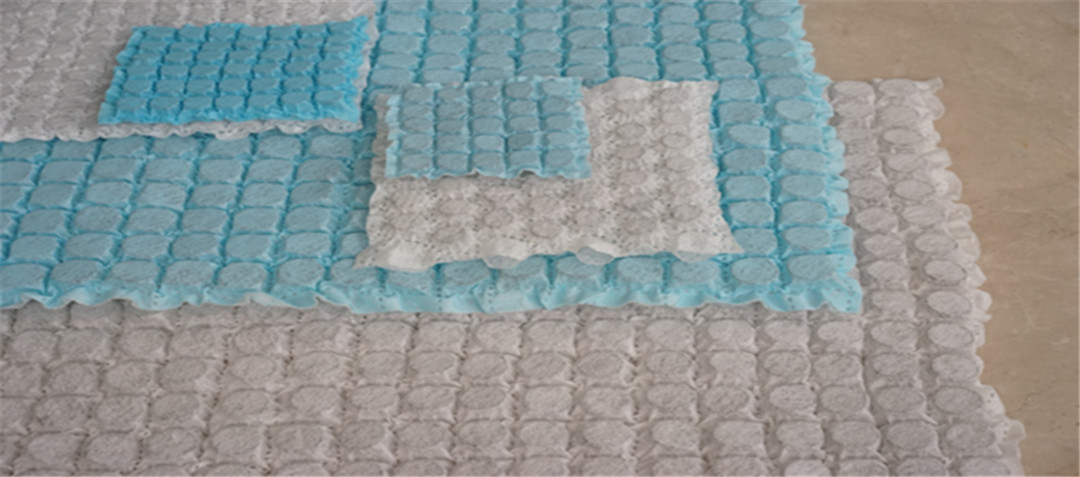

Pocket spring core with zoning

A simplified version of the ergonomic bed core. According to the pressure distribution during sleep, the bed core can be divided into head, shoulder, back, waist, hip and leg areas, each area requires different softness and firmness, the bed core provides different support, the comfort of this bed core is greatly improved compared to the ordinary pocket spring bed core.

The production of zoned pocket spring cores is usually carried out using a double wire pocket spring production machine. The machine is equipped with two different wire feeds and once the user has set the parameters on the machine, the machine is able to automatically switch between the steel wires when production reaches the corresponding area, thus enabling the automatic production of zoned pocket spring cores.

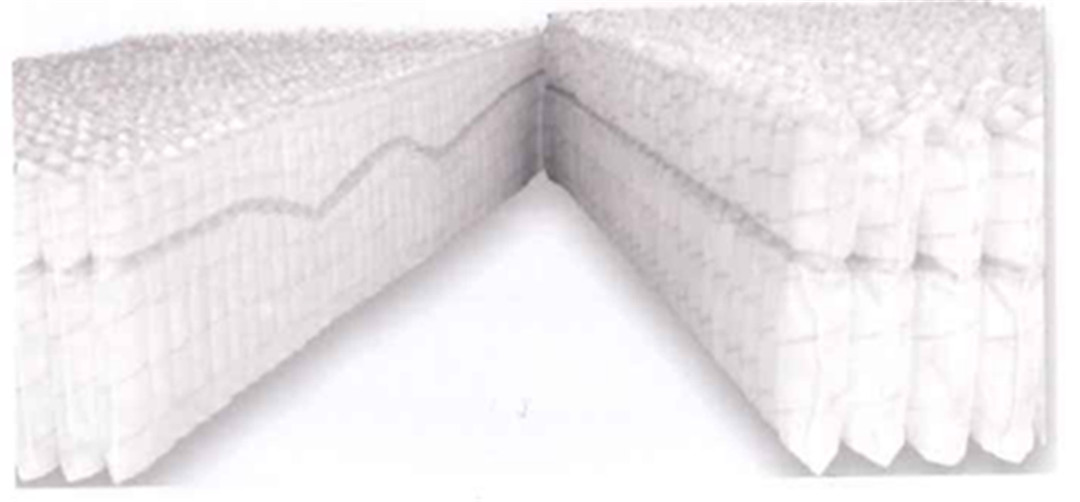

Double-layer pocket spring core

A double-layer graduated pocket spring core, ergonomically designed to match the pressure distribution curve of the human sleeping posture.Suitable for personalisation and to provide optimum comfort.

Lianrou Machinery's LP-PS-DL double pocket spring production machine is the only automatic production machine in the country and abroad that can handle this type of personalisation and its core patents have won China's national patent awards. The top and bottom layers of the mattress are welded together in one piece without glue, making the product more environmentally friendly and healthier.

High density pocket spring mattress core

The springs have a smaller waist diameter, a tighter arrangement, more support points, better quietness and better comfort. Suitable for high-end customisation, a bed core needs to use up to 3-4 thousand springs.

Bendable and movable pocket spring mattress cores

Special pocket spring core. The most important feature is that it can be freely bent and is suitable for electric mattresses, folding mattresses, moveable sofas, etc. By tilting or bending the pocket, the springs encapsulated in the pocket are not in an upright position, leaving enough space for the mattress to flex. The number of springs used in the production of mattress cores can be reduced by a third.

Pocketed spring pillow core

The advantages of pocket spring pillow cores are outstanding: good support, not deformed; good breathability, not stuffy; good comfort, less fibre, less odour.

Ultra-thin multi-purpose pocket spring core (box spring mattress)

Widely used, suitable for mattresses, sofas, cushions, upholstery materials, etc., with a certain sponge replacement function, no glue and no odour, the product is more environmentally friendly and healthier.

Post time: Apr-21-2023