Pocket spring production machine is a special equipment used to produce pocket spring. It is widely used in the upholstered furniture industry where pocket spring is used as the main elastic support, such as pocket spring mattresses. Upholstered furniture made of pocket spring has the advantages of independence, quietness, breathability, environmental protection and so on. Especially the pocket spring mattress, its good resilience, stable support, high durability, popular in the upholstered furniture market.

Guangzhou LIANROU Machinery &Equipment Co., Ltd. is a global leader in the field of pocket spring machines. In May 2023, at the COLOGNE GERMANY INTERZUM, it launched a spring machine (LR-PS-EV280/260) with a maximum productivity of 280 springs/min., which is 30% ahead of similar products in terms of productivity.

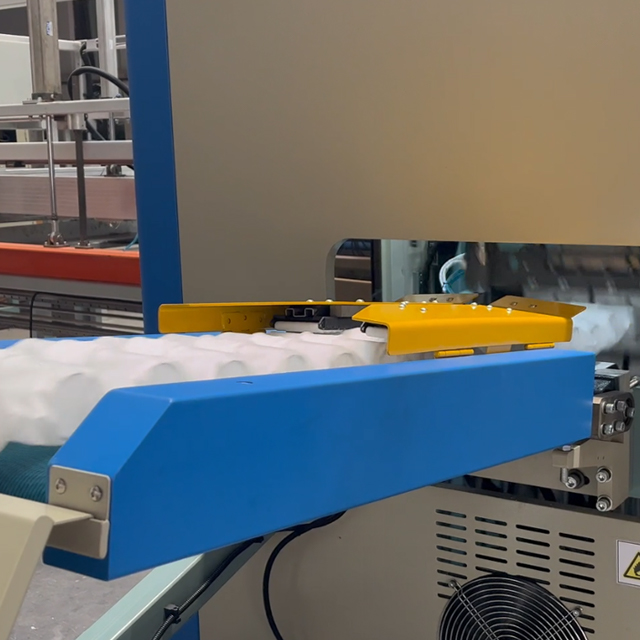

In the same industry, when only a very small number of equipment to achieve the production efficiency of 200 springs/min., the production efficiency of this machine has reached a staggering 280 springs/min., and its production efficiency is even up to twice as much as some similar machines, bringing great pressure to similar machines. Only as an upholstery manufacturer and related equipment companies, it is possible to understand the difficulty of its related technology. heat-treatment of steel wire, spring coiling, spring transportation, pocketing encapsulation welding and other related processes respond to the milliseconds, especially after a series of processes completed in a very short period of time, but also without affecting the performance of springs. In addition, pocket spring mattresses made from it can be compressed, folded, rolled and packed for a long period of time, and once released, they quickly rebound and regain their supportive capacity.

After investigating the mystery, we found that GuangZhou LIANROU Machinery﹠Equipment Co., Ltd. has mastered a large number of related invention patents, such as steel wire heat-treatment, spring cooling transmission, spring encapsulation welding method and so on all have invention patents.

First, from the structural design point of view, the machine adopts an E-shaped structural design so that it can accommodate more magnetic bases. During the production process, the magnetic base adsorbs the freshly coiled springs and cools them during the transfer process, which accurately achieves the heat-treatment process and ensures that the springs are cooled to the appropriate temperature when they are encapsulated in the pocket. In addition, the design of this E-shaped structure also reduces the size of the equipment, thus saving space and freeing up more space in the customer's production facility.

Patents for Inventions: ① Spring steel wire heating coiling and cooling transfer device, the invention is a key invention of the spring heat-treatment process. ② A double wire heat-treatment temperature detection device and method, the invention is another key invention of the spring heat-treatment process, through the two temperature detection mechanism in real time to obtain the temperature of the two wires, so that the continuous production of each spring have the same heat-treatment effect, to ensure that the spring production quality. ③A double wire feed coiling spring molding device, high production efficiency and realize the key invention of automatic partition function.

In addition to the above main invention patents, there are patents on spring pocketing-encapsulation-welding related inventions, as well as a number of utility patents technology applications, these are still only part of its production efficiency technology patents, some other core technology aspects, manufacturers have technical confidentiality requirements, can not be disclosed.

The product in addition to high production efficiency, there is a high rate of qualified products, the production process can meet the spring automatic deviation correction and quality monitoring, the production of pocket spring unit after 100,000 times of rolling test, does not affect its performance; After a long time of compression, once the mattress is released, it can quickly rebound to the appropriate height and restore the elastic support performance. This machine is an excellent choice for pocket spring mattress manufacturers to reduce costs and increase efficiency.

In addition, a series of industry-leading products have been launched by LIANROU Machinery.

In 1998, LIANROU Machinery developed the first mechanical driven Pocket Spring Machine in China

In 2008, LIANROU Machinery developed an automatic box spring production machine that can produce an ultra-thin pocket spring unit without glue, making the use of pocket springs more widespread.

In 2014, LIANROU Machinery developed a new generation of fully automatic spring production line with a productivity of 140 springs/min., ahead of its time in the industry.

In 2015, LIANROU Machinery developed the industry's first double-layer pocket spring production machine, making the concept of personalized mattress customization to human curves a reality for the first time;

In 2016, LIANROU Machinery launched a double wire pocket spring machine, leading the whole industry, so that the function and efficiency of spring machine and further improve, to meet the demand for high-speed automatic production of mattresses with soft and hard zoning.

In 2018, LIANROU Machinery introduced a new curved pocket spring production machine that allows pocket spring mattresses to be used in the field of electric beds, while reducing the cost of spring unit production.

According to the information obtained, LIANROU Machinery also developed for the first time a green non-glue pocket spring unit production equipment, a high compression ratio pocket spring production equipment, it can reduce the weight of pocket spring mattress, as well as a variety of mattress packing equipment, etc. In the field of upholstered furniture automation equipment, LIANROU Machinery is the absolute leader.

LIANROU Machinery also has industry-leading design capability, which has been awarded as the Industrial Design Center of Guangdong Province, and has designed mattress intelligent production workshop and automatic assembly line for many mattress manufacturers, and has also designed customized products for many enterprises. It has developed a smartline intelligent management system, which is a tailor-made intelligent management system for mattress manufacturers, integrating various intelligent production elements, which can greatly improve production efficiency and reduce production costs for mattress manufacturers.

Post time: Jul-25-2023