Pocket spring production equipment is specialised equipment used for the efficient production of pocket springs, including pocket spring production machines, pocket spring assembly machines for bedding and pocket spring roll packaging machines for bedding and mattresses.

History of development: In 1925, Simmons was the first to invent the production of independent pocket spring machine, independent pocket spring production from manual to semi-mechanical to mechanical transfer and then to CNC, after more than one hundred years of development, the current has entered the field of intelligent manufacturing.

Ⅰ. Pocket Spring Machines:

1. Classified according to productivity:

Type I: Productivity > 200 springs / min, belongs to the current most advanced and high quality pocket spring production equipment, the representative product model for the LR-PS-EV280, the productivity of the world's first, up to 280 springs / min.

Type II: production efficiency of 120-200 springs / minute, this production efficiency range is the current more common technical level, but the reliability of the various brands of equipment, durability and other differences.

Type Ⅲ: production efficiency This classification by productivity is not scientific and can only distinguish between regular models and functional pocket spring machines. There are some special models that do not fit into this classification, for example the high density, high diameter to waist ratio pocket spring machine, which is difficult to produce due to its special characteristics, has reached a productivity of 100 springs/minute, which is already a world leader.

2. Classified by the number of wire feeds

Type I: 1-Wire Pocket Spring Machines: Conventional models for producing common, uniform sizes of individual pocket springs. These are the longest established and most technically mature pocket spring machines.

Type II: 2-wire pocket spring machines: two different sizes of wires at the same time, can produce pocket spring bed net with zoning function. Emerged in the past 10 years, the use of two different sizes of wire feed spring winding, can be high-speed fully automatic production of zoning function pocket spring bed net, to meet the easy personalisation of mattresses.

Type Ⅲ: 4-wire pocket spring machines: 4 wires feeding at the same time, with ultra-high production efficiency and perfect mattress ergonomics personalisation performance. Representative product double pocket spring production line LR-PS-4WL, 4 wires feeding at the same time, the production of double pocket spring bed net, with ultra-high production efficiency and mattress personalisation features. The product LR-PSLINE-BOX4W is a 4-line box spring production line with two double wire heads for ultra-high speed production of box springs.

3. Classification by function

Ordinary type: the more routinely used pocket spring machine with single line feed, higher production efficiency and the most popular model.

Partition type: Generally a two line feed pocket spring machine capable of producing 5, 7 and 9 zone pocket spring bed nets.

Double layer type: The firmness of different positions of the mattress is controlled by changing the height of the upper and lower pocket springs, this pocket spring production machine is of a high technical level.

High compression ratio type: the spring encapsulated in the bag is in a higher state of compression, which can increase the hardness of the pocket spring bed net, i.e. it is possible to use finer steel wires to produce harder pocket spring bed nets, and the use of this type of equipment can effectively reduce the cost of raw materials and reduce the weight of the bed net.

High density pocket spring bed net production machine: a production of high-end pocket spring mattress equipment, a mattress 3,000-4,000 independent pocket springs, more support points, elastic feedback is more accurate, more comfortable.

Spring special arrangement type: Commonly used independent pocket spring is upright arrangement, the pocket spring produced by this equipment is tilted arrangement or arc-shaped arrangement, the spacing between the spring is larger, the bed net can be bent at will to meet the electric bed, electric sofa and other upholstered furniture that can be bent to meet the use. Used for ordinary bed net, can also reduce the number of springs by one-third, reduce the cost, reduce the weight of the bed net.

Box spring production machine: it can produce one-piece ultra-thin box spring, the production of ultra-thin box spring is widely used, many scenarios to replace the use of sponge.

Pillow pocket spring production machine: For the production of a small pocket spring, used in the pillow in the core elastic support layer, with breathable and comfortable and other characteristics, the production of the pillow has a good selling point.

II. Independent pocket spring assembly machine:

Pocket spring assembly machine is a special equipment to glue the pocket springs produced by the pocket spring production machine into the bed net, through the core of the adhesive melter to melt the hot melt adhesive, the glue is sprayed evenly on the side of the pocket spring string, and the rows are glued into the bed net. There are mainly manual models, automatic models and multi-functional models.

Manual model: It is necessary to manually put in the cut pocket spring rows, the production efficiency is low.

Automatic model: One assembly machine can be connected to 1-3 pocket spring machines for fully automatic production of pocket spring bed nets with high efficiency and great labour savings.

Multi-functional model: In addition to the basic function of fully automatic bonding of the pocket spring bed net, it is also possible to automatically bond other materials around the bed net, to reinforce the pocket spring bed net around the bonded comfort materials, with a higher degree of automatic bonding.

Non-adhesive pocket spring bed net welding machine: Pocket spring strings are welded into pocket spring bed net by ultrasonic welding, which changes the traditional adhesive bonding, and it is the latest kind of environmentally friendly non-adhesive pocket spring bed net production technology in 2023.

Ⅲ、Individual pocket spring bed net / mattress roll packing equipment:

They are divided into bed net packaging equipment and mattress packaging equipment, this type of packaging equipment is mainly used for two purposes: one is to reduce the volume of the mattress / bed net, easy to transport; the second is dustproof, moisture-proof, anti-scratch, the mattress / bed net to do the appropriate protection, but also easy to transport. Bed net is generally used as the core support layer of upholstered furniture production, belongs to a raw material for mattresses, many mattress companies directly purchase pocket spring bed net, so there are special equipment will be dozens of pocket spring bed net compression roll package, greatly reducing the volume of packaging, easy to transport.

Compression wrapping machine: It is suitable for wrapping multiple pocket spring bed nets and also single mattresses. Packaging equipment to compress the bed net / mattress through the hydraulic compression platform, 30cm thickness of the mattress / bed net can be compressed to a thickness of 3cm, both sides packed by the PE film, and then wrapping, become a cylindrical shape, greatly reducing the volume of the mattress / bed net.

Compression, folding and roll-packing machine: Based on compression roll-packing, it can further reduce the volume, bed net/mattress compression, one or two folding, and then roll-packing, you can put a 200cm x 200cm pocket spring mattress in a box with a side length of 60cm, which facilitates e-commerce sales and transport of mattresses, and at the same time the mattresses are no longer subject to the limitations of narrow lift and narrow door when entering the user's home.

Flat packaging machine: Generally used for high-end mattresses or mattresses with edges that can't be compressed, these are packed using UV sterilisation, dust removal and other processes, and then encapsulated through multiple layers to protect against dust and moisture.

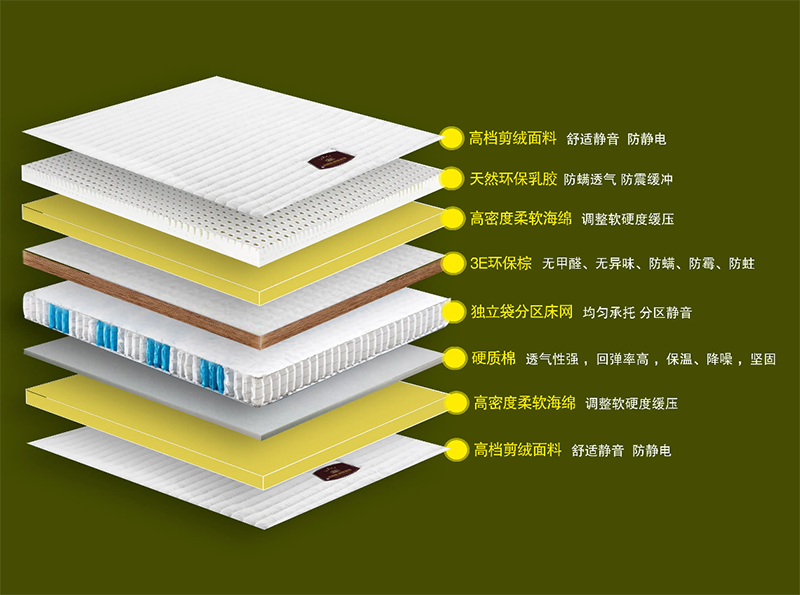

Composite independent pocket spring mattress, by independent pocket spring bed net as the core support layer, at the bottom and the periphery to increase the comfort layer of materials (sponge, latex, memory foam, etc.), made of composite mattresses, this application is the most widely used in mattresses, high comfort, can experience the independent pocket spring mute characteristics and the comfort of other materials.

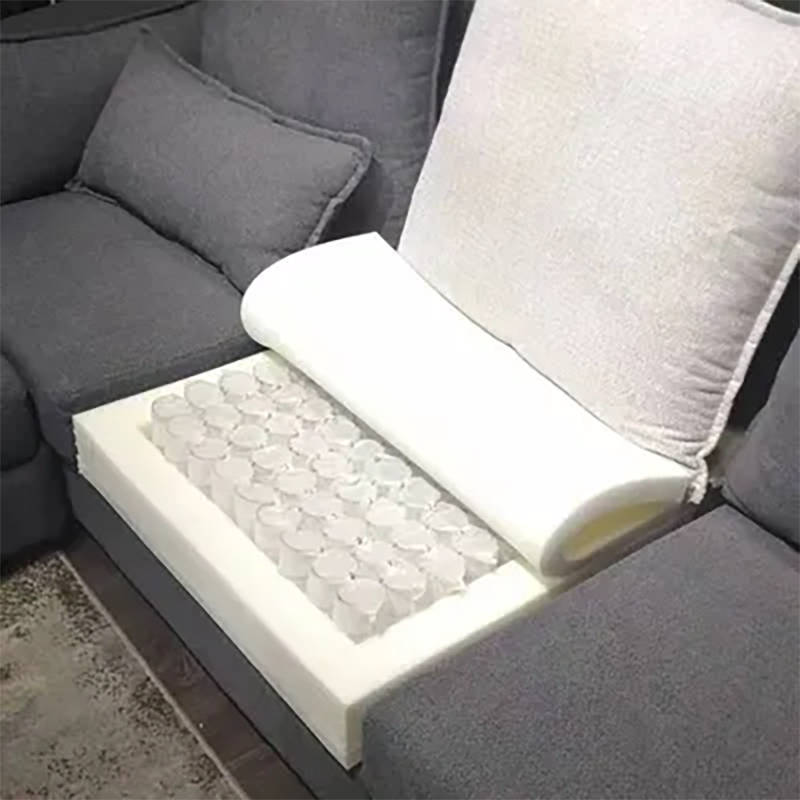

Emerging applications - Sofas

Pocket springs can be made to any height and bonded to any size, which is why they are increasingly being used in sofas. In sofa cushions in particular, independent pocket springs are used as the core support layer and the outer layer is wrapped in sponge, providing both support and comfort.

An ultra-thin box spring unit that also replaces foam as the comfort material in the back of a sofa, providing durability and breathability.

Unexpected application - pillows

Independent pocket spring equipment, technological advances, you can produce a small mini independent pocket spring, will be used in the pillow as the core support, resilience performance, support performance, comfort and breathability of the outstanding, the market has been widely used, and as a selling point.

Applications in Development - Seats

Trains, high-speed trains, aircraft and other means of transportation, the number of seats is huge, the space is narrow, the fire safety requirements are higher, the current seat is basically sponge material. The advantages of independent pocket springs are more obvious, independent pocket springs only the outer layer of non-woven fabric is flammable material, compared with the sponge, less flammable parts, and burning without thick black smoke, will not quickly spread the fire. In addition, the permeability of the independent pocket spring is also better than the sponge. High-speed rail, train ride for a long time, the seat better breathability can also give passengers a better experience.

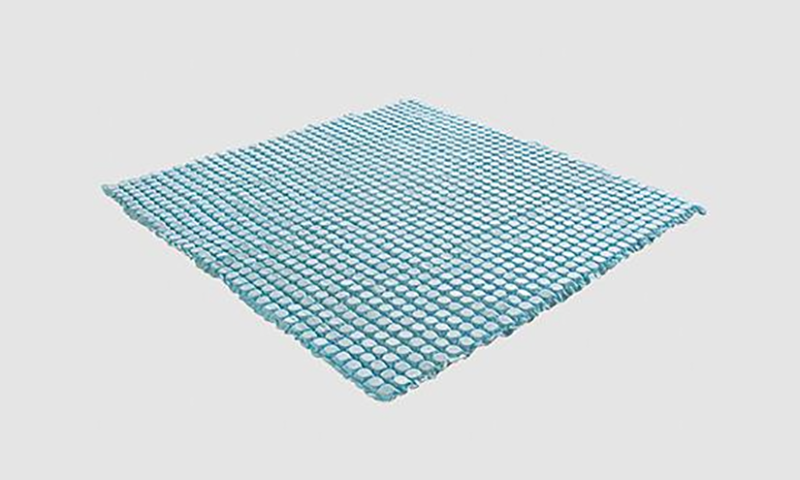

Other Comfort Seats

Replacing the foam with an ultra-thin pocket spring cushion not only acts as a comfort layer but also provides better support, is more durable than foam and will not collapse. Stand-alone pocket spring cushions are already available on the market.

Pocket springs VS sponge

Independent pocket springs compared to sponge, the advantages are outstanding, moisture-proof, environmental protection, breathable, but also has a greater disadvantage, that is, the weight is heavier than the sponge, in the production and transportation process always increases the cost, so there is no advantage in price. Commonly used sponge is made of substances extracted from oil, so the price of sponge is affected by the price of oil; when the price of oil is high, every manufacturer tends to use pocket springs to make upholstered furniture; when the price of oil is low, manufacturers tend to use sponge material.

Post time: Dec-27-2023