Lianrou Machinery- The world's leading premium supplier of solutions for fully automatic mattress production lines

Product Introduction

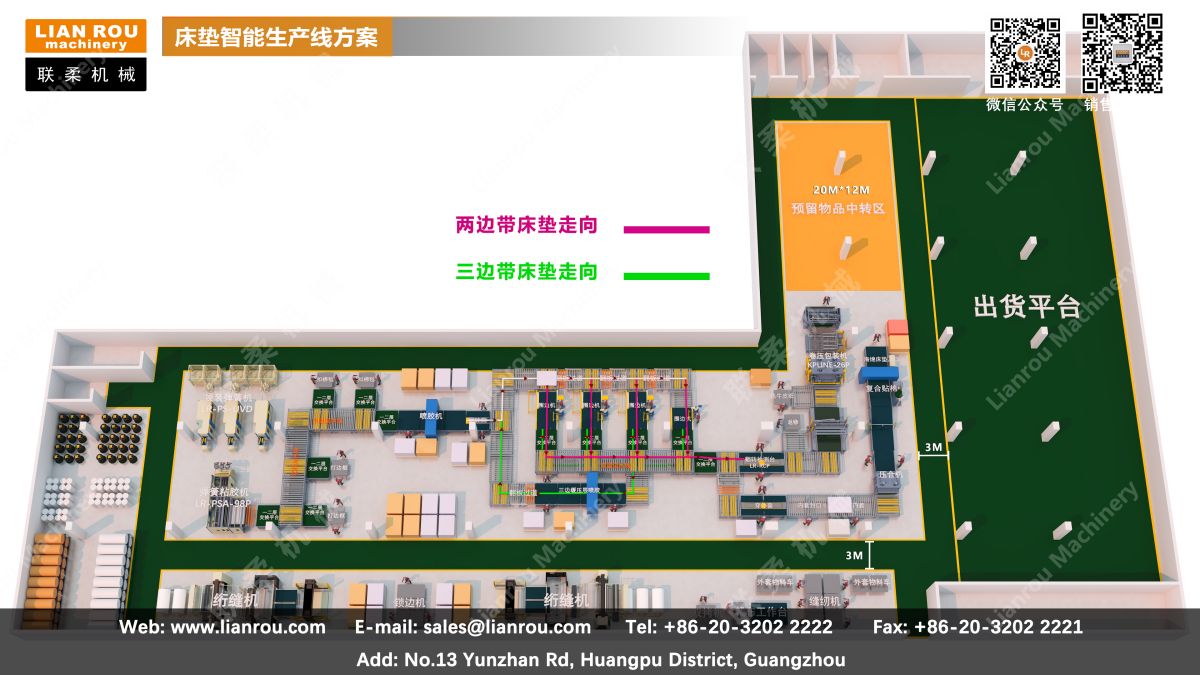

This mattress production line solution covers the entire process of pocket spring mattress production, including pocket spring production, rounding process, laminating process, packaging process, etc. It uses components such as Turning Detection Table, Power Roller Conveyor Line, Belt Conveyor Line, Lift Traverse Feeder, Reversing Platform, Production Line Exchange Platform, etc., which have a service life of more than 15 years. It can realise various sizes and different thicknesses of mattresses in the production process of feeding, automatic mattress composite pasting cotton, automatic detection, automatic packaging and other functions. High degree of automation, one set of assembly line a day (8h) can achieve 500 mattresses production, great saving in labour cost.

Cost budget and production process

Production efficiency: 30-60 seconds to produce and pack a mattress.

Combined labour savings: 10

Space occupied: approx. 1600m²

Budget Cost: Pocket spring machine (standard model) 2-3 sets

Pocket Spring Assembly Machine (high speed) 1 set

Automatic mattress roll-packing machine, 1 set

Composite laminating machine, 1 set

Automatic glue spraying machine, 2 sets

Flip detection table, 2 sets

Power roller conveyor line 140 meters

Belt conveyor line 45 meters

Lift-traverse feeder 32 sets

Reversing platform, 1 set

Laminating machine, 1 set

Production line exchange platform, 11 sets

Flap Aisle, 5 sets

Rotating table, 6 sets

Mattress rounding machine, 4 sets

Case sealing machine, 1 set

Total cost 0.5-0.7 million

Process Introduction

1. Production of pocket spring bed net: The pocket spring bed net is produced by the pocket spring production machine together with the assembly machine.

Automatic gluing and bonding: The gluing machine sprays glue around the pocket springs, automatically bonding the comfort layer.

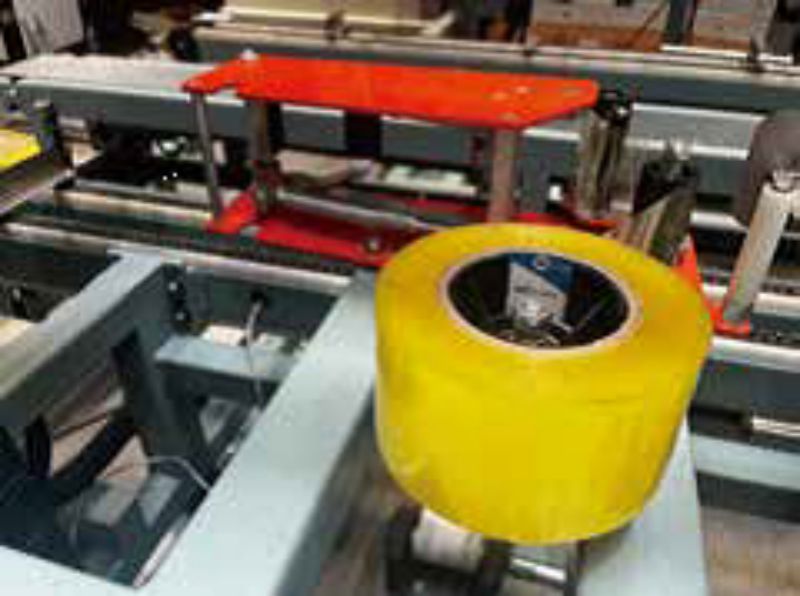

4 Roll-packing: compressed and rolled packaging for finished mattresses, then boxed.

5. Other mattress packing: can be connected to foam mattress and other composite mattresses at the same time for roll-packing, through the composite laminating machine to paste the foam compression, the inner sleeve, the outer sleeve sealing, through the conveyor belt to the roll-packing machine for compression and packing.

Technical characteristics

Using SMART LINE intelligent platform to realize intelligent management, it can realize equipment monitoring, production process synchronization, failure analysis, cost management, quality traceability, intelligent scheduling, performance assessment, report statistics, etc., and at the same time, it can satisfy the needs of remote operation and maintenance and remote debugging.

Lianrou machinery(https://www.lianrou.com) is dedicated to the research, development and production of high-level, high-tech, high-performance upholstery equipment to solve the production problems of downstream industries. To provide comprehensive support for industrial upgrading, intelligent production and digitalisation.

The related upholstered furniture production equipment sells well in more than 80 countries and regions such as Europe, North America, South America, Southeast Asia, etc., and the main customers include IKEA, Sealy, Yalan, Simmons, Serta and other international famous home furnishing enterprises.

The company has a number of provincial R & D platform qualification, a professional R & D design team, including upholstered furniture hardware equipment design and development and related software development, is committed to solving a variety of problems in the upholstered furniture manufacturing industry. There have been a number of design achievements that have been recognized by the industry, including non-glue pocket spring bed net production solutions, low-cost pocket spring bed net production solutions, various mattress packaging solutions. We can also design and customize various personalized solutions according to customer needs.

Post time: Dec-12-2023