Application of individual pocket springs

In 1870, Simmons invented the wire bed, the prototype of the spring mattress. In 1900, Vispring invented the world's first independent pocket spring mattress and was the first to file a patent in Canada. In 1925, Simmons invented the independent pocket spring machine, which ushered in the era of industrial production of independent pocket spring mattresses and was protected by a 50-year patent. Until after 2000, with the innovation of automated production technology, production cost reduction, production efficiency has been greatly improved, independent pocket spring has gradually become the mainstream of the mattress market.

1、Widest application - mattresses

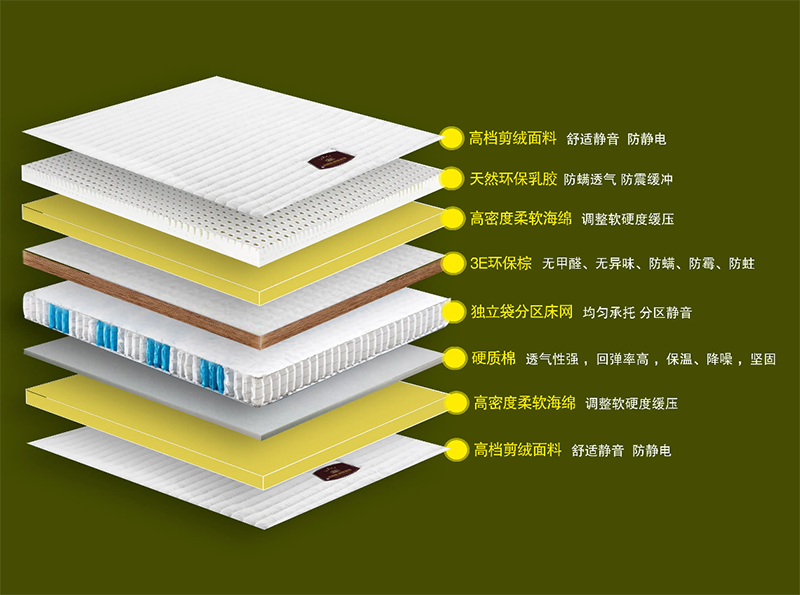

Individual pocket spring mattresses are made from pocket springs with an outer fabric wrap to form the mattress. These mattresses are cost effective and offer a certain level of comfort.

Composite independent pocket spring mattress, by independent pocket spring bed net as the core support layer, at the bottom and the periphery to increase the comfort layer of materials (sponge, latex, memory foam, etc.), made of composite mattresses, this application is the most widely used in mattresses, high comfort, can experience the independent pocket spring mute characteristics and the comfort of other materials.

Emerging applications - Sofas

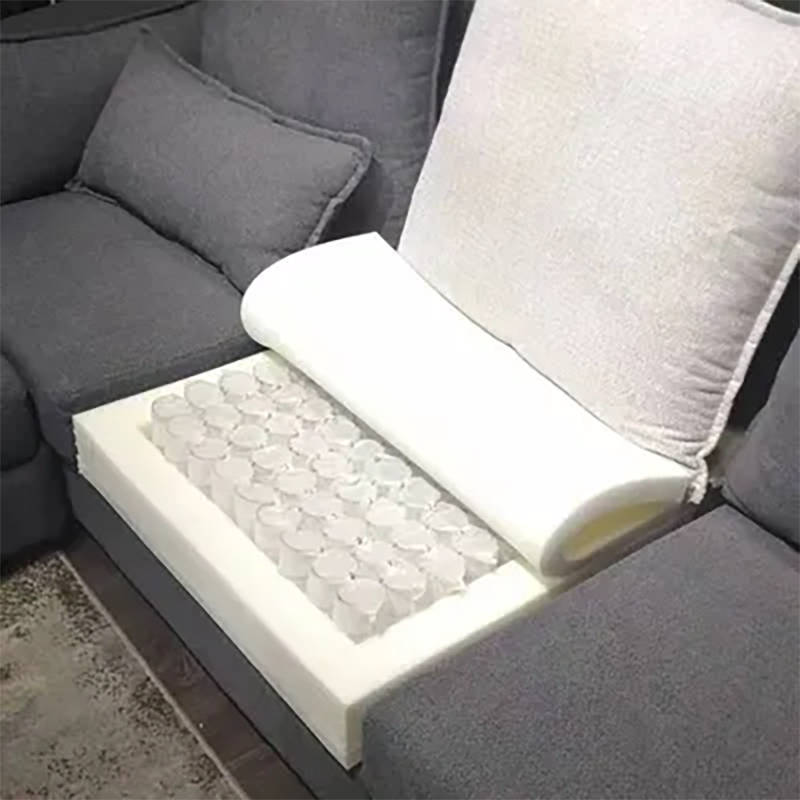

Pocket springs can be made to any height and bonded to any size, which is why they are increasingly being used in sofas. In sofa cushions in particular, independent pocket springs are used as the core support layer and the outer layer is wrapped in sponge, providing both support and comfort.

An ultra-thin box spring unit that also replaces foam as the comfort material in the back of a sofa, providing durability and breathability.

Unexpected application - pillows

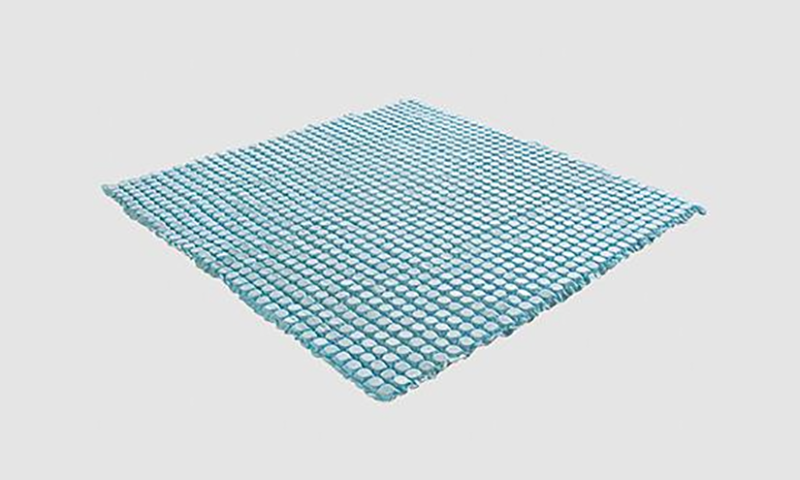

Independent pocket spring equipment, technological advances, you can produce a small mini independent pocket spring, will be used in the pillow as the core support, resilience performance, support performance, comfort and breathability of the outstanding, the market has been widely used, and as a selling point.

Applications in Development - Seats

Trains, high-speed trains, aircraft and other means of transportation, the number of seats is huge, the space is narrow, the fire safety requirements are higher, the current seat is basically sponge material. The advantages of independent pocket springs are more obvious, independent pocket springs only the outer layer of non-woven fabric is flammable material, compared with the sponge, less flammable parts, and burning without thick black smoke, will not quickly spread the fire. In addition, the permeability of the independent pocket spring is also better than the sponge. High-speed rail, train ride for a long time, the seat better breathability can also give passengers a better experience.

Other Comfort Seats

Replacing the foam with an ultra-thin pocket spring cushion not only acts as a comfort layer but also provides better support, is more durable than foam and will not collapse. Stand-alone pocket spring cushions are already available on the market.

Pocket springs VS sponge

Independent pocket springs compared to sponge, the advantages are outstanding, moisture-proof, environmental protection, breathable, but also has a greater disadvantage, that is, the weight is heavier than the sponge, in the production and transportation process always increases the cost, so there is no advantage in price. Commonly used sponge is made of substances extracted from oil, so the price of sponge is affected by the price of oil; when the price of oil is high, every manufacturer tends to use pocket springs to make upholstered furniture; when the price of oil is low, manufacturers tend to use sponge material.

Post time: Dec-21-2023