Products

97P 550 springs/min Full automatic and semi-automatic manual spring coiling assembly machine

| Model | LR-PSA-97P | |

| Production capacity | Max.550 springs/min | |

| Hot melt application system | Nordson(USA)or Robatech(Switzerland) | |

| Capacity of glue tank | 18KG | |

| Gluing method | Spot spray,continuous spray and general economic mode | |

| Possibility of assembling zoned tape | Available | |

| Possibility of assembling zoing mattress | Available | |

| Air consumption | Approx 0.3m³/min | |

| Air pressure | 0.6 ~ 0.7 mpa | |

| Power consumption in total | 13KW | |

| Power requirements | Voltage | 3AC 380V |

| Frequency | 50/60Hz | |

| Input current | 25A | |

| Cable section | 3*10m㎡+2*6m㎡ | |

| Working temperature | +5℃~ +35ºC | |

| Weight | Approx.4300Kg | |

| Consumption Material Data | |

| Non-woven fabric | |

| Fabric density | 65~80g/㎡ |

| Fabric width | 450~2200mm |

| Inner dia.of fabric roll | Min.60mm |

| Outer dia.of fabric roll | Max.600mm |

| Hot Melt Glue | |

| Shape | Pellet or pieces |

| Viscosity | 125℃---6100cps 150℃--2300cps 175℃--1100cps |

| Softening point | 85±5℃ |

| Working range(mm) | |

| Pocket Spring Waist Diameter | Pocket Spring Height |

| φ37~75 | 55~250 |

Automatic Mode

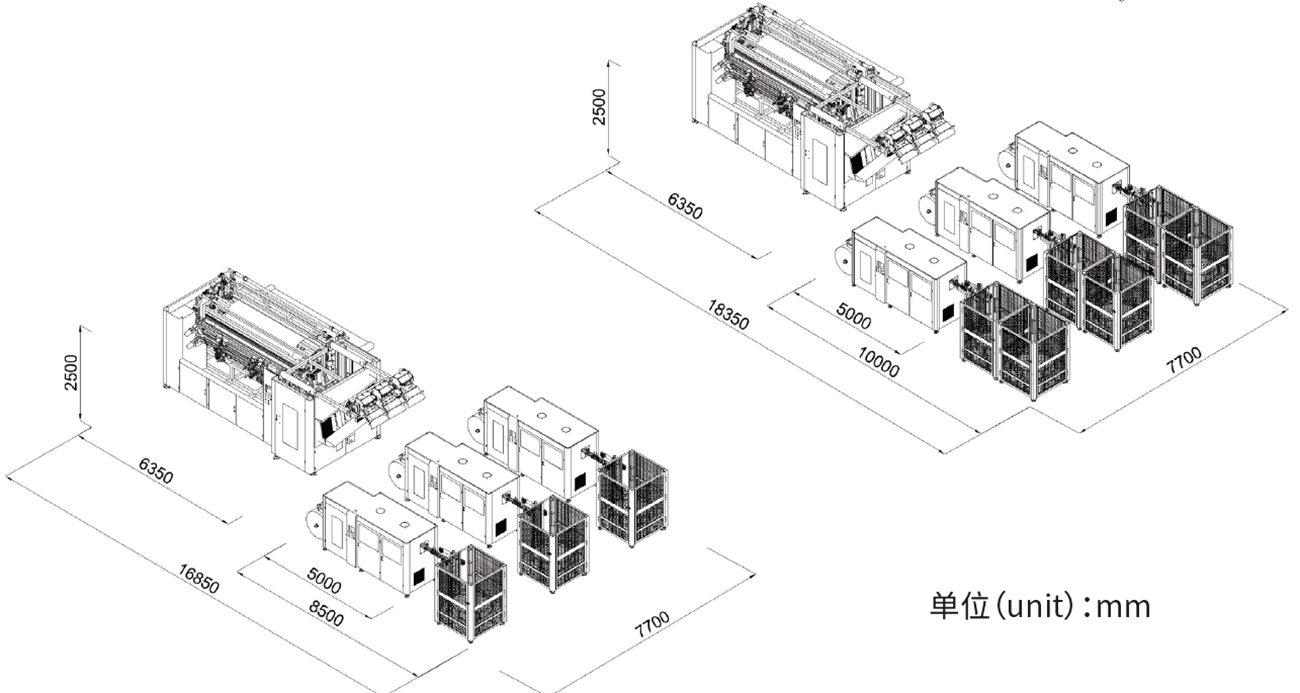

Manual automatic all-in-one pocket spring assembly machine LR-PSA-97P

The machine can be combined with three spring machines to form a "3 dragged by 1" production line

Manual mode

1.Free switching between the three channels, thus increasing feeding efficiency

2.Spraying and feeding of the spring bars are carried out simultaneously without interference

3.Adhesive efficiency up to 17 rows per minute, and economical benefits

4.The machine is equipped with a "manual mode",Manual loading of spring rows under the protection of the grating sensor, safe and efficient

Cost Saving

1.The equipment can be used to recycle qualified spring rows that have been misjudged by other automatic assembly machine to produce mattresses

2.In addition, the machine is suitable for the production of special mattress samples and customized mattresses

The perfect replacement for the customer's existing semi-automatic assembly machine

Two modes

1.Two modes - manual and automatic - to meet the different needs of customers

FAQ

1) Can we choose colors for your products?

Our products come in fixed colors and specifications. However, if you can meet our MOQ, we can customize the color of the product.

2) What are the advantages of your spring machine?

We offer patented technologies that provide the highest production efficiency in the industry. We also offer multiple production plans to choose from.

3) What are the benefits of your glue machine?

Our glue machine is efficient and saves on adhesive usage. Running speed can reach up to 30 rows per minute, and we offer manual, automatic, double-row, and multi-face glue equipment. Our glue machine is suitable for continuous or intermittent gluing, easy to operate and maintain.